ASF-EU

More

The REGIUS fibre laser cutting machine integrates 3-axis linear drive, AMADA’s original Variable Beam Control technology, the new Laser Integration System (LIS) functions and easy operation.

The extremely high speed, precise accuracy of full linear drive technology maximizes machine potential and minimizes downtime. Common processing issues are solved thanks to several autonomous functions such as automatic beam centring and advanced process monitoring, enabling a shift to next level laser processing.

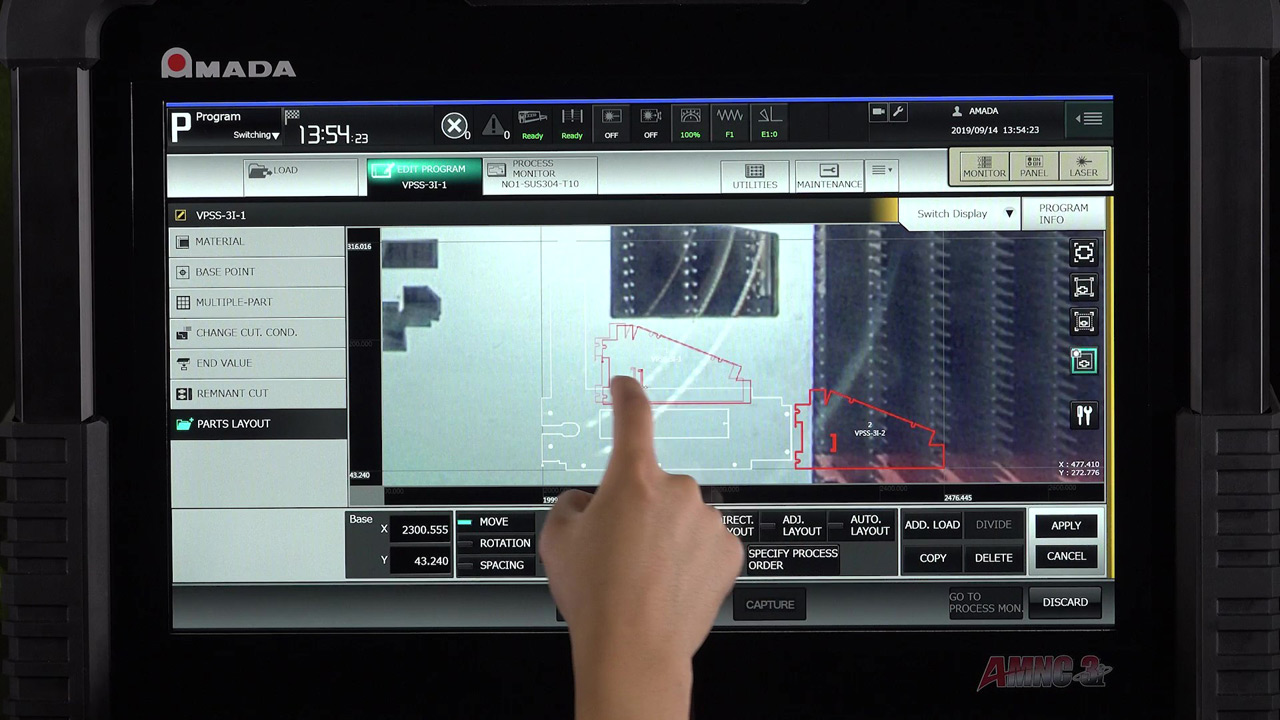

i-CAMERA ASSISTED SYSTEM (i-CAS):

This camera based system allows parts to be manually nested on material remnants placed anywhere on the cutting bed. Rotating, copying and placing are simple and quick to help improve remnant utilization.

V-REMOTE:

The AMNC 3i control screen can be shared on iPads anywhere in the factory, enabling flexible production such as amending schedules and adding urgent jobs.

FRONT AND SIDE ACCESS:

In order to provide a high level of accessibility to the cutting area, the REGIUS is equipped with 3 gull wing side doors and a fully sliding end door as standard.

| REGIUS-3015AJ | REGIUS-3015AJ | REGIUS-3015AJ | |

|---|---|---|---|

| Laser power (W) | 6000 | 9000 | 12000 |

| Machine type | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine |

| Working range X x Y (mm) | 3070 x 1550 | 3070 x 1550 | 3070 x 1550 |

| Working range Z-axis (mm) | 100 | 100 | 100 |

| Repeatable positioning accuracy (mm) | ± 0.01 | ± 0.01 | ± 0.01 |

| Table loading weight (kg) | 920 | 920 | 920 |

| Drive system | Linear drive | Linear drive | Linear drive |

Material thickness (max.)*: | |||

| - Mild steel (mm) | 25 | 25 | 25 |

| - Stainless steel (mm) | 25 | 25 | 25 |

| - Aluminium (mm) | 25 | 25 | 25 |

| - Brass (mm) | 15 | 18 | 18 |

| - Copper (mm) | 12 | 12 | 12 |

Dimensions: | |||

| Length (mm)** | 10346 | 10346 | 10346 |

| Width (mm) | 2990 | 2990 | 2990 |

| Height (mm) | 2450 | 2750 | 2520 |

| Weight (kg) | 11900 | 12000 | 12100 |

| REGIUS-4020AJ | REGIUS-4020AJ | REGIUS-4020AJ | |

|---|---|---|---|

| Laser power (W) | 6000 | 9000 | 12000 |

| Machine type | Fibre laser cutting machine | Fibre laser cutting machine | Fibre laser cutting machine |

| Working range X x Y (mm) | 4070 x 2050 | 4070 x 2050 | 4070 x 2050 |

| Working range Z-axis (mm) | 100 | 100 | 100 |

| Repeatable positioning accuracy (mm) | ± 0.01 | ± 0.01 | ± 0.01 |

| Table loading weight (kg) | 1570 | 1570 | 1570 |

| Drive system | Linear drive | Linear drive | Linear drive |

Material thickness (max.)*: | |||

| - Mild steel (mm) | 25 | 25 | 25 |

| - Stainless steel (mm) | 25 | 25 | 25 |

| - Aluminium (mm) | 25 | 25 | 25 |

| - Brass (mm) | 15 | 18 | 18 |

| - Copper (mm) | 12 | 12 | 12 |

Dimensions: | |||

| Length (mm)** | 12174 | 12174 | 12174 |

| Width (mm) | 3199 | 3199 | 3199 |

| Height (mm) | 2450 | 2750 | 2520 |

| Weight (kg) | 14900 | 15000 | 15100 |

* Maximum thickness value depends on material quality and environmental conditions

** Machine + shuttle table (LSTe)

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.

Laser class 1 when operated in accordance to EN 60825-1