Improve your laser cutting machine capabilities with AMADA VPSS 4ie Blank software. With advanced pre-set parameter configurations for different machine models, even less experienced operators can create machine programs. With its powerful automated functions, this CAM software delivers a reliable and efficient solution for nesting complex parts.

With minimal effort, you can considerably enhance the performance and efficiency of your laser cutting machine. This translates to increased output with fewer mistakes, enabling you to create higher quality products in a shorter amount of time.

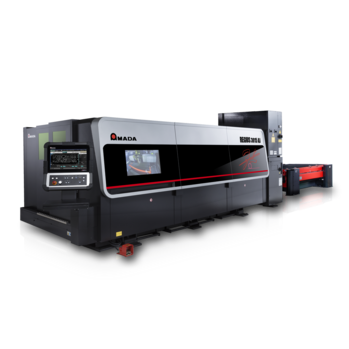

Error-free, AMADA software solutions help you preventing machine downtime. Take full advantage of AMADA laser machines' capabilities. Fully automated can be used even by less experienced operators.

Some images do not include hazard prevention measures.